40 Years of Experience and Insights from the Desk of Doug Pelleymounter

Posted January 06, 2020 by Doug Pelleymounter

I’ve been a field application engineer for Advanced Energy for 22 years and I’m ready to take the next step in my career: retirement. As I hurtle toward this milestone, I remind myself to continue contributing every day, and I keep in mind that while I have been part of and witnessed truly remarkable innovation, it’s the relationships I’ve built with colleagues and customers that matter most.

I’ve been asked to put not just 22 but over 40 years in the thin film industry into perspective, point out what I think have been significant innovations as well as steady drivers of development, and maybe even pass on a little advice. Please don’t stop reading here.

Drastically Ramping Up Productivity

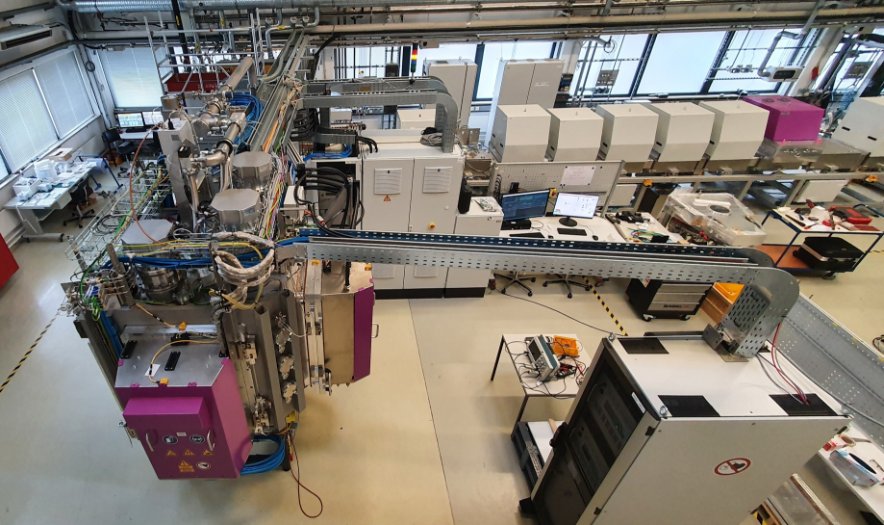

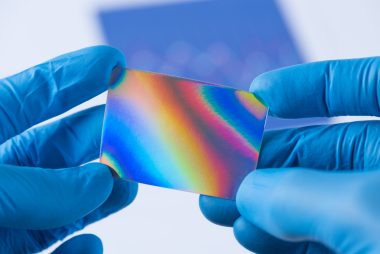

To start, let’s turn the clock back to the 1980s, when I was first getting involved with sputter deposition, coating processes, and process implementation related to thin films. Back then, thermal evaporation was the mostly accepted PVD technique and production rates were terribly uneven. Our goals were to make the process “better, faster, cheaper” while improving thin film quality from batch to batch. Sound familiar? My team was working on thermal control materials for NASA; at that point, I was a user of Advanced Energy power supplies. We decided to try direct current (DC) sputtering, and found that it gave us 5X the rate of deposition that RF sputtering could deliver, and two hundred nanometers thickness with a bit better stress control. We also worked to change the operating parameters such that we would be sputtering towards the middle of the hysteresis curve, thereby achieving another 2-3X increase in productivity. With those changes, we said “goodbye” to evaporative deposition for a lot of subsequent processes.

Then, like now, it was understood that if you can make even incremental improvements to productivity without compromising quality, especially with smart investment in production equipment, you could make a big difference to the bottom line. Then, like now, what engineers don’t want is to get a call at two o’clock in the morning because the equipment has failed or the process is struggling – which is why spending money on reliable equipment and top personnel pays off.

Achieving Repeatability

Accuracy is important but repeatability is paramount in the thin film industry. The advent of the graphical user interface, along with RS-232/485 connectivity and PLCs, enabled a huge step forward in achieving repeatability. While we didn’t have the diagnostic capabilities of today – we literally had a wall of relay ops controlling the process – the early technologies that led to Ethernet and Profibus connectivity gave us the ability to “put more square feet in the box, and pull more good square feet out of the box.” We often talk about yield at AE, or as I say, “good square feet.”

Modern computing horsepower, data analysis along with the Industrial Internet of Things, artificial intelligence and machine learning are inspiring innovation as much if not more than ever. Repeatability is still the Holy Grail, and today our customers have more process visibility, intelligent systems and the responsive precision power they need to find, and hold onto, that level of repeatability.

Customer Service

In the 1990s, I was working in a flat panel coating enterprise in Minnesota that depended on Advanced Energy’s PE30K Series AC generators for its livelihood. One day, our power supply failed, the downtime costing us about $6,000/hour – big money at the time. I called AE and whined a lot for help as we were dead in the water, the team in Ft. Collins heard this and without missing a beat put a replacement supply on a plane in Denver and I picked it up in Minneapolis hours later. That was my first experience with AE customer service, and it got me thinking that AE was a company I wanted to be part of. Not only were they into pretty cool stuff, they really took care of customers. When the opportunity to join the company came along, I jumped at it. Our customers and even our competitors will tell you that exceptional customer support is still a hallmark, and differentiator, for AE.

Pivotal Thin Film Technology Innovations

There have been many steps forward in thin films since the advent of my career at AE. Here are a few that I think have made huge differences, what we now call disruptive technologies. Lots of folks out there have laid awake long nights to figure out stuff like the following points below.

- Rotatable cathodes – reducing the amount of unwanted macroparticles from being deposited

- Advanced target materials – the ability to better utilize suboxide targets such as Indium tin oxide and Titanium suboxides to run faster and with greater stability

- The transition from analog to digital communication and control – allowing for whole systems to be run not only with immense precision, but remotely and even from a smartphone

- Summation of different power delivery systems – for example RF and DC on a single cathode so we can synchronize totally different power delivery systems.

- AC style of power delivery to keep anodes clean and processes running for weeks at a time

- High Power Impulse Magnetron Sputtering (HiPIMS) – which was pioneered by AE more than a decade ago and is now creating real production benefits

One of the important lessons relevant to our industry is that we are wary of breaking highly effective processes just for the sake of innovation. It’s essential to be able to easily revert to a legacy system at a moment’s notice if the new whiz-bang box fails to deliver as advertised. It is satisfying to be on the “bleeding edge” of technology when it all works out. Please remember that if you are not out on the edge, you are probably taking up too much space.

The healthy skepticism my customers have exhibited has always kept me thinking in new ways. That, and innovations such as HiPIMS, almost make me want to put retirement off for another year or two. After writing that statement I went and laid down – the HIPIMS is still cool but I am indeed retiring.

My Two Cents Worth

Innovation is king. It’s the way we can rise above the noise in the marketplace. Creating synergies with our customers is also essential. Our customers are hungry to further tighten processes, and we brainstorm with them all the time to find ways to make that happen.

I’ll sum up my thin film career by making two remarks. First, my advice to anyone in Advanced Energy and elsewhere, for that matter, is that if you don’t know something, say so right up front. Go find the answer and follow up in a timely manner.

Finally, it’s that the people I’ve grown to know over my 40 years are the salt of the Earth, bound by the mutual desire to work past challenges together. I know that even after I retire, I’ll remain in touch with many of you. And so, rather than “goodbye,” I’ll say, “see you down the road.”

.jpg?resizemode=force&maxsidesize=884)