Sustainability Through Power Conversion Innovation

Posted January 11, 2023 by Peter Gillespie

Electricity generation is responsible for around 27% of the estimated 51 billion tons of greenhouse gases added to the earth’s atmosphere every year. Moves to achieve ‘Net Zero’ emission targets often rely on increasing rather than decreasing electrification. Therefore, we need to make better use of the electricity that is generated and to enable renewable energy.

One of the keys to achieving both of these objectives is the development of more energy efficient power conversion technologies across critical industrial applications.

AE’s dedicated R&D teams strive to improve power conversion efficiency, balanced with exceptional stability and nimble control and response. Every increase in power conversion efficiency reduces our customers’ power consumption and decreases their environmental impact and carbon emissions.

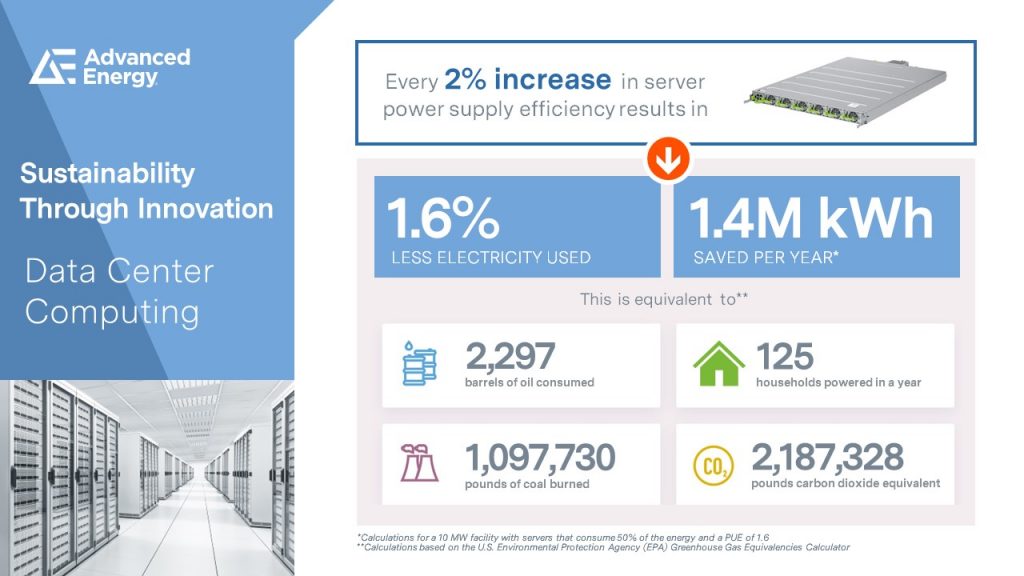

As an example, consider the data centers, which already account for at least 3% of worldwide energy use. As digital transformation increases and data center power consumption continues to grow, it is imperative that this growth is met without a corresponding increase in energy consumption.

While data centers have traditionally used 12 V power shelves for distribution to servers, 48 V architecture is increasingly being adopted. With 4x less current and 16x lower distribution losses compared to 12 V, 48 V delivers better thermal performance, with smaller busbars and increased efficiency. Recognizing the benefits that can be achieved by 48 V architecture, Advanced Energy’s Artesyn™ Open Compute ORv3 (Open Rack v3) platform is a key enabler for the adoption of 48 V rack power for hyperscale data centers.

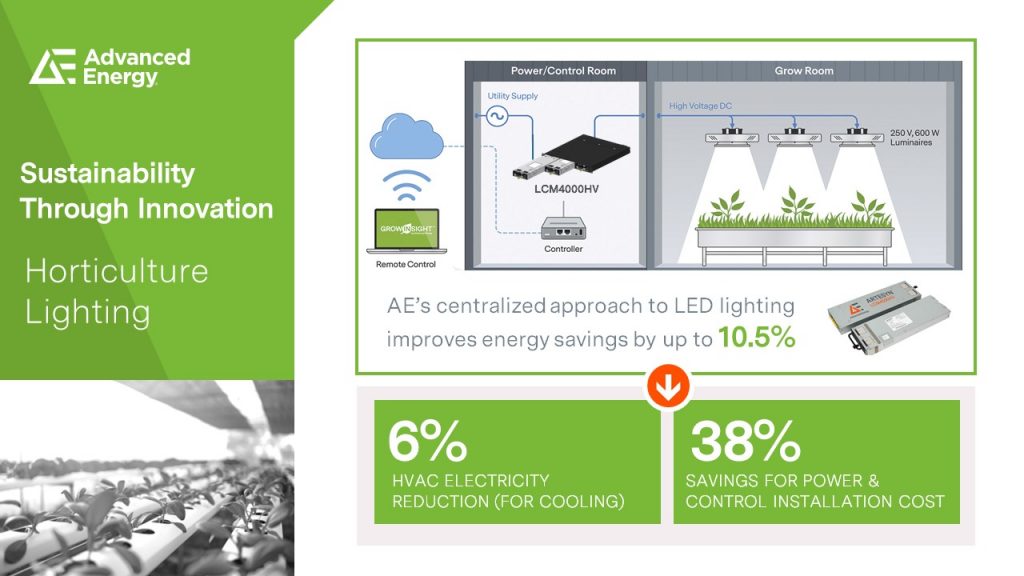

In the rapidly expanding indoor horticulture applications – a sector that is likely to become more pervasive as climate change impacts traditional crops growing methods and countries focus on reducing reliance on crops that need to be shipped over significant distances.

Here, one area where significant energy savings can be made is in changing the way the high-power LEDs, essential to crop growth, are powered and managed. Moving from distributed power to centralized power architectures that provide a single point of power conversion not only improves LED lighting efficiency but also reduces the need (and, therefore, the electricity required) for cooling the growing area.

Advanced Energy’s Artesyn LCM4000HV delivers DC power with up to 95% efficiency for a novel, centralized lighting scheme, while the Advanced Energy GROWINSIGHT™ horticultural monitoring and control system enables growers to optimize growing conditions that further reduces electricity use. For example, for crops that require specific intermittent hours of light and darkness, GROWINSIGHT enables the creation of smart lighting schedules.

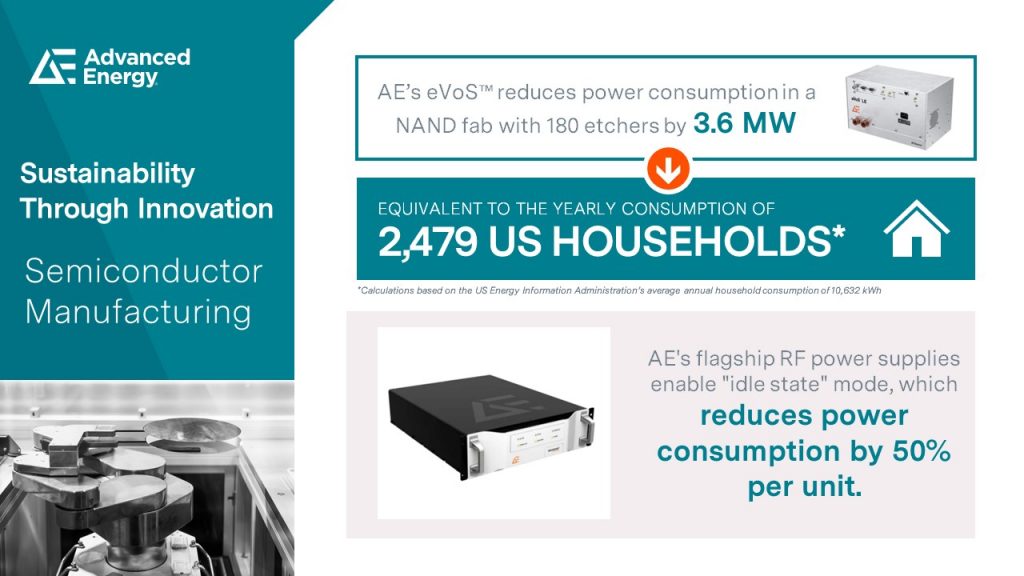

Semiconductor manufacturing is another high electricity usage application where the appropriate selection of power supply and conversion technology delivering more accurate process control and more targeted power can make a significant difference to energy consumption. As an example, the latest plasma power supplies and matching networks provide power only where it is needed, ensuring maximum efficiency with the least wasted energy – even as semiconductor fabrication processes become complex and power-hungry.

Advanced Energy’s eVoS™ asymmetric waveform generator, for instance, provides highly targeted power delivery. Unlike traditional sinusoidal RF power sources, eVoS enables the production of near monoenergetic ion energy distributions (IEDs) that deliver power only where the plasma needs it, reducing energy lost to reflected power and heat.

As with semiconductor manufacture, many complex production processes in which thin films and coatings are deposited on substrates require the precise and efficient control of power. One example is in the growth of thin films for the LEDs that consumes only a fraction of the energy of traditional incandescent bulbs. This also applies to the manufacture of the latest energy-efficient LED TVs and monitors.

Here, the key to keeping power consumption as low as possible while creating high-quality films is to choose DC, pulsed DC and low-frequency AC power supplies that deliver stable, high-efficiency, accurate and repeatable power control for the thin film sputtering in the highly specialized manufacturing process.

Sustainability Through Innovation

With its focus on designing and manufacturing highly engineered power conversion, measurement and control solutions, Advanced Energy is at the forefront of innovations that improve efficiencies in the example areas mentioned above – and many more precision power applications including telecommunications, medical equipment and industrial automation.

But we do much more than simply build ever-more efficient power supplies and process power solutions. By shaping and transforming the way that power is used, delivered and managed, we create and enable the technologies that are critical to making better use of global energy resources, reducing the world’s reliance on fossil fuels and minimizing greenhouse gas emissions.

You can find out more about how Advanced Energy’s innovations are helping to cut global electricity use in this white paper.

.png?resizemode=force&maxsidesize=884)